Diesel Generators | Reliable Power Solutions

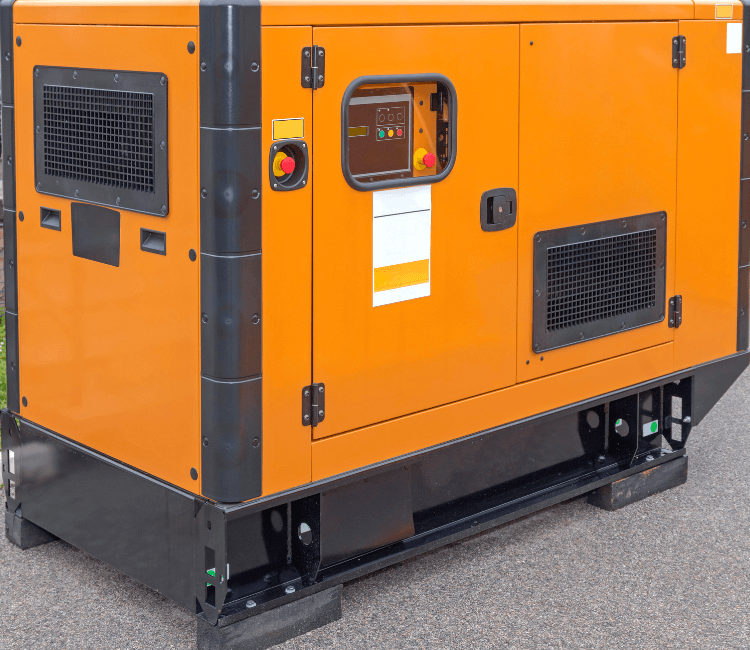

ZAJCO SA provides high-performance Diesel Generators from world-leading manufacturers like Cummins, Perkins, MTU, Caterpillar, and KOHLER. We deliver complete power solutions, including expert installation, implementation, maintenance, and Annual Maintenance Contracts (AMC) to ensure uninterrupted power supply across Saudi Arabia, India, Qatar, and Oman.

Description

In today’s interconnected world, reliable power is non-negotiable for business continuity, safety, and operational efficiency. ZAJCO SA specializes in providing robust Diesel Generators that deliver dependable primary or backup power for diverse applications across Saudi Arabia, India, Qatar, and Oman. As a trusted leader in Electro-Mechanical Engineering and integrated solutions, we deal with renowned brands such as Cummins, Perkins, MTU, Caterpillar, and KOHLER to offer a superior range of generators known for their durability, efficiency, and performance.

Our comprehensive Diesel Generator solutions are ideal for:

- Emergency Standby Power: Ensure critical operations continue seamlessly during unexpected power outages, safeguarding data, equipment, and safety.

- Prime Power Generation: Provide consistent power for remote sites, construction projects, or facilities off the main grid.

- Peak Shaving: Reduce reliance on grid power during peak demand times, optimizing energy costs.

- Data Centers & IT Infrastructure: Critical for preventing data loss and downtime in sensitive technological environments.

- Healthcare Facilities: Maintain essential medical equipment and life support systems during power disruptions.

- Industrial & Commercial Buildings: Support manufacturing processes, retail operations, and large commercial complexes.

Key features and advantages of ZAJCO SA’s Diesel Generators:

- Unwavering Reliability: Built for continuous operation and proven performance, ensuring power is available when you need it most.

- Fuel Efficiency: Modern diesel engines are designed to maximize fuel economy, reducing operational costs.

- Diverse Power Outputs: A wide range of capacities (kVA/MW) to match specific power requirements, from small businesses to large industrial plants.

- Durable & Robust Construction: Engineered to withstand harsh environmental conditions and demanding continuous operation.

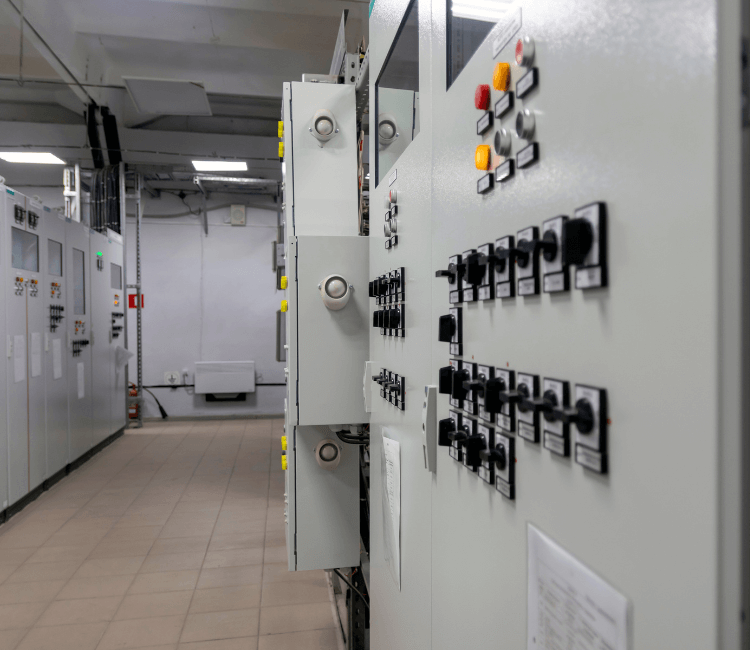

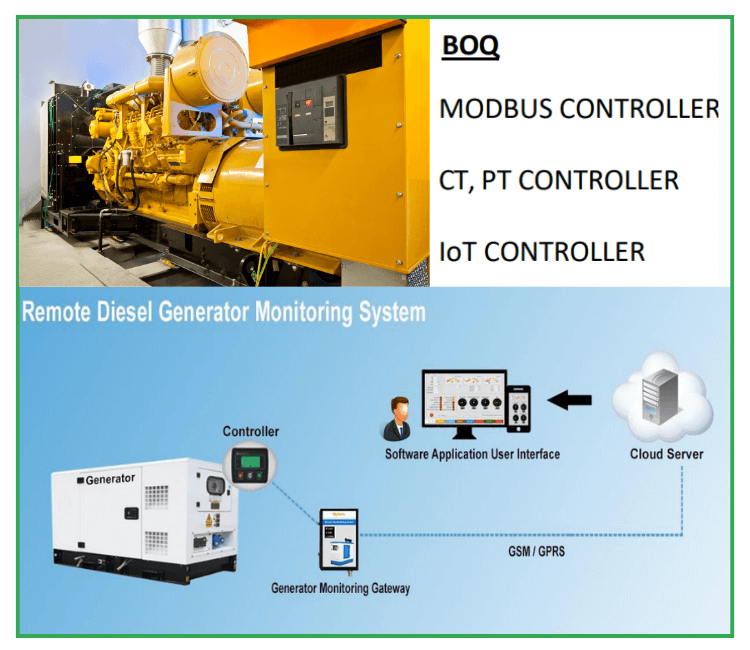

- Advanced Control Systems: Equipped with intelligent automatic transfer switches (ATS) and monitoring systems for seamless power transitions and remote management.

- Lower Maintenance Cycles: Diesel generators generally require less frequent maintenance compared to other fuel types.

ZAJCO SA provides comprehensive, end-to-end services to ensure your Diesel Generator is flawlessly implemented and continuously performs at its peak:

- Expert Installation: Our certified electro-mechanical engineers ensure precise and safe installation, including civil works, fuel systems, exhaust systems, and electrical connections, adhering to all standards.

- Seamless Implementation & Commissioning: We manage the entire setup, testing, and commissioning process, ensuring your generator is fully operational and integrated with your power system.

- Proactive Maintenance: Regular inspections, routine servicing, filter replacements, fluid checks, and diagnostic testing to maximize lifespan and prevent unexpected failures.

- Comprehensive Annual Maintenance Contracts (AMC): Our AMCs offer dedicated support, rapid troubleshooting, genuine spare parts, and preventive servicing, guaranteeing the longevity, efficiency, and peak performance of your generator investment across KSA, India, Qatar, and Oman.

Deal with ZAJCO SA for intelligent, reliable, and integrated power generation solutions from trusted brands like Cummins, Perkins, MTU, Caterpillar, and KOHLER.”

Know more about Diesel Generator:

- What is a Diesel Generator?

A diesel generator, often called a genset, is a combination of a diesel engine and an electric generator (alternator). It converts the mechanical energy from the engine into electrical energy, providing a reliable source of power. - How does a Diesel Generator work?

The diesel engine burns diesel fuel to create mechanical energy, which then drives the alternator. The alternator, through electromagnetic induction, converts this mechanical energy into electrical power (AC current). - What are the main applications of Diesel Generators?

Diesel generators are widely used for:- Standby/Backup Power: For homes, hospitals, data centers, and commercial buildings during grid outages.

- Prime Power: As the sole source of power in remote locations (e.g., construction sites, mining operations, remote camps).

- Peak Shaving: Supplementing grid power during periods of high demand to reduce electricity costs.

- Emergency Power: Critical systems in airports, telecommunication towers, and vital infrastructure.

- What are the key benefits of Diesel Generators?

Key benefits include:- Reliability & Durability: Known for robust construction and long lifespan, especially for heavy-duty use.

- Fuel Efficiency: More fuel-efficient than gasoline generators, particularly under high loads, leading to lower operating costs.

- Low Maintenance: Fewer moving parts compared to other engine types, resulting in less wear and tear.

- Safety: Diesel fuel is less flammable than gasoline, reducing fire hazards.

- Versatility: Available in a wide range of sizes and configurations for various applications.

- What are the main types of Diesel Generators by application?

The main types are:- Standby Generators: Automatically kick in during power outages, typically for short-term use.

- Prime Generators: Designed for continuous operation as the primary power source.

- Portable Generators: Smaller, movable units for temporary power needs.

- Industrial Generators: Large, heavy-duty units for continuous or high-demand commercial/industrial use.

- What are the core components of a Diesel Generator?

The essential components are:- Engine: The power source (diesel engine).

- Alternator (Generator Head): Converts mechanical energy to electrical energy.

- Fuel System: Fuel tank, pump, filters, injectors.

- Cooling System: Radiator, fan, coolant.

- Exhaust System: Muffler, exhaust pipes.

- Lubrication System: Oil sump, pump, filters.

- Control Panel: For operation, monitoring, and fault display.

- Voltage Regulator: Maintains a stable output voltage.

- Frame/Enclosure: Housing for the components, often soundproofed.

- How is generator size typically measured (kVA vs. kW)?

Generator size is usually measured in kVA (kilovolts-amperes) for apparent power and kW (kilowatts) for real power. kW is the actual power used by the load, while kVA is the total power delivered. The power factor (PF) relates kW to kVA (kW = kVA x PF), typically 0.8 for most loads. - What is an Automatic Transfer Switch (ATS), and why is it important?

An ATS is a critical component for standby generators. It automatically detects power outages, starts the generator, transfers the load from the utility grid to the generator, and reverses the process when grid power is restored. This ensures seamless power continuity without manual intervention. - How noisy are Diesel Generators, and are there silent options?

Diesel generators can be noisy, especially larger industrial units. However, many modern generators come with sound-attenuated or “silent canopy” enclosures that significantly reduce noise levels, making them suitable for noise-sensitive environments like residential areas or urban commercial buildings. - What are the common fuel consumption rates for Diesel Generators?

Fuel consumption varies significantly with generator size (kVA), load percentage, and engine efficiency. Generally, larger generators consume more fuel, and consumption increases with the load applied. For example, a 100 kVA generator at 75% load might consume around 20-25 liters/hour. - What are the safety features integrated into Diesel Generators?

Common safety features include automatic shutdown for low oil pressure, high engine temperature, overspeed, overcurrent, and low fuel levels. They also have emergency stop buttons and protective enclosures. - What kind of regular maintenance do Diesel Generators require?

Regular maintenance is crucial for reliability and longevity. It typically includes: routine oil and filter changes, coolant level checks, fuel system checks (water separators, filters), battery inspection, air filter cleaning/replacement, and visual inspections for leaks or damage. - Are Diesel Generators suitable for extreme ambient conditions like those?

Yes, reputable diesel generators and their cooling systems are designed to operate reliably in high ambient temperatures, such as those found in the UAE, often with specific cooling packages for extreme heat. - What are “Prime” and “Standby” power ratings for generators?

Prime Power (PRP) is the maximum power a generator can supply continuously under varying loads for an unlimited number of hours per year. Standby Power (ESP) is the maximum power a generator can supply during a utility power outage for up to 200 hours per year, with varying loads. - What range of Diesel Generators does ZAJCO SA.com provide?

ZAJCO SA.com states that they can provide specialized diesel generator packages across most industries. While their page lists typical applications, the general range of diesel generators available in the market, often supplied by such providers, extends from small units (e.g., 10-50 kVA) to very large ones (e.g., 2000 kVA and beyond). Their mention of “project-specific packages” suggests a tailored approach. - Does ZAJCO SA.com’s generator offering include specific engine brands like Perkins, Cummins, or John Deere? While ZAJCO SA.com’s general description doesn’t name specific engine brands on the provided snippets, reputable generator package providers like them typically use engines from world-renowned manufacturers such as Perkins, Cummins, John Deere, Volvo Penta, MTU, or Caterpillar, which are known for their reliability and performance.

- What additional services does ZAJCO SA.com offer beyond just supplying generators?

ZAJCO SA.com emphasizes providing “specialized diesel generator packages” and that their “engineering team provides the optimal solution every time.” This implies comprehensive services including design, build, testing (in accordance with ISO 9001), installation, commissioning, and likely after-sales support and maintenance. - Are there options for “Twin Start” or “Extended Service Intervals” in ZAJCO SA.com’s offerings?

Yes, ZAJCO SA.com explicitly mentions “Twin start” and “Extended service intervals” as specific applications or features for their diesel generator packages, indicating advanced customization and reliability features available to clients. - What are the typical considerations when selecting a Diesel Generator for a project in the GCC?

Key considerations in the GCC include: required power output (kVA/kW), prime vs. standby application, fuel efficiency, noise level regulations (especially for urban areas), extreme ambient temperature operation capabilities, exhaust emission standards, fuel storage solutions, maintenance intervals, local support availability, and compliance with local utility regulations. - Why choose a specialized provider like ZAJCO SA.com for Diesel Generators?

Choosing a specialist ensures that the diesel generator package is designed, built, and tested as a “project-specific package” in accordance with ISO 9001, guaranteeing optimal performance for the harsh climate and specific client needs. They provide tailored engineering solutions, ensuring reliability, compliance with local standards, and likely comprehensive after-sales support.