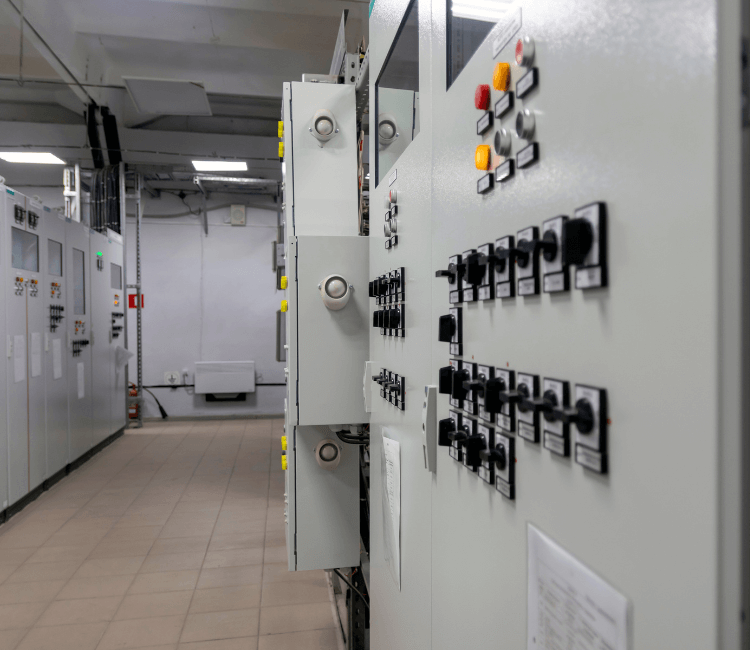

Medium & Low Voltage Switchgears

ZAJCO SA delivers comprehensive Medium & Low Voltage Switchgears and Electrical Panels from leading brands like Schneider Electric, ABB, and Siemens. We provide end-to-end solutions, including expert installation, implementation, maintenance, and Annual Maintenance Contracts (AMC) to ensure safe and reliable power distribution across Saudi Arabia, India, Qatar, and Oman.

Description

The backbone of any robust electrical infrastructure lies in its power distribution and protection systems. ZAJCO SA specializes in providing state-of-the-art Medium & Low Voltage Switchgears and Electrical Panels, ensuring safe, reliable, and efficient power management for commercial, industrial, and utility sectors across Saudi Arabia, India, Qatar, and Oman. As experts in Electro-Mechanical Engineering and integrated solutions, we deal with industry giants such as Schneider Electric, ABB, Siemens, Eaton, and Larsen & Toubro (L&T) to deliver unparalleled quality and performance.

Our comprehensive Switchgears & Electrical Panels solutions encompass:

- Medium Voltage Switchgears: Designed for controlling, protecting, and isolating electrical equipment in large facilities, ensuring stability and preventing outages. Ideal for industrial plants, power stations, and large commercial complexes.

- Low Voltage Switchgears & Distribution Boards (DBs): Essential for safely distributing power to various circuits and equipment within a building. They provide critical protection against overloads, short circuits, and ground faults, ensuring operational continuity.

- Motor Control Centers (MCCs): Centralized assemblies for controlling motors, providing protection, control, and automation functionalities for industrial processes.

- Power Control Centers (PCCs): Designed for efficient distribution and control of electrical power in main distribution areas.

- Custom-Built Panels: We design and fabricate bespoke electrical panels to meet specific project requirements, ensuring optimal functionality and compliance with all safety standards.

Key features and benefits of ZAJCO SA’s Switchgears & Electrical Panels solutions:

- Uncompromised Safety: Engineered with advanced protection mechanisms to safeguard personnel and equipment from electrical hazards.

- Exceptional Reliability: Built with high-quality components from renowned manufacturers, ensuring continuous and stable power supply.

- Operational Efficiency: Optimize power consumption and reduce energy losses, leading to significant cost savings.

- Advanced Control & Monitoring: Integrate with Building Management Systems (BMS) for intelligent control, remote monitoring, and predictive maintenance capabilities.

- Compliance & Standards: All solutions adhere to international and local electrical safety standards and regulations.

- Future-Proof Design: Modular and scalable designs allow for easy expansion and upgrades as your power demands evolve.

ZAJCO SA provides comprehensive, end-to-end services to ensure your Switchgears & Electrical Panels are flawlessly implemented and continuously perform at their peak:

- Expert Installation: Our certified electro-mechanical engineers ensure precise installation of all switchgear components and electrical panels, adhering to the highest safety and quality standards.

- Seamless Implementation: We manage the entire integration process, including wiring, testing, and commissioning, ensuring a smooth transition and optimal performance.

- Proactive Maintenance: Regular inspections, preventive maintenance, thermal imaging, and component checks to extend the lifespan of your equipment and prevent costly downtimes.

- Comprehensive Annual Maintenance Contracts (AMC): Our AMCs offer dedicated support, rapid troubleshooting, and preventive servicing, guaranteeing the longevity, safety, and peak performance of your electrical infrastructure investment across KSA, India, Qatar, and Oman.

Deal with ZAJCO SA for intelligent, reliable, and integrated power distribution solutions from trusted brands like Schneider Electric, ABB, Siemens, Eaton, and L&T.”

Know more about Medium & Low Voltage Switchgears :

- What is Switchgear?

Switchgear is a general term for electrical equipment that controls, protects, and isolates electrical circuits in a power system. It includes various components like circuit breakers, switches, fuses, relays, and associated control devices. - What is Low Voltage (LV) Switchgear?

Low Voltage (LV) Switchgear operates at voltages typically below 1,000 volts AC (or 1,500V DC). It’s used to distribute power safely and efficiently to end-user equipment and circuits within residential, commercial, and light industrial settings. - What is Medium Voltage (MV) Switchgear?

Medium Voltage (MV) Switchgear operates at voltages generally ranging from 1 kV to 36 kV (though sometimes up to 52 kV). It’s crucial for primary and secondary power distribution in utility substations, large industrial facilities, and data centers. - What are the primary functions of both LV and MV Switchgears? Their primary functions are:

- Protection: Safeguarding equipment and personnel from overloads, short circuits, and other electrical faults.

- Control: Managing the flow of electricity (turning circuits on/off).

- Isolation: Disconnecting specific parts of the electrical system for maintenance or repair safely.

- Measurement: Monitoring current, voltage, and other electrical parameters.

- What are the key components commonly found in low-voltage switchgear?

LV switchgear typically includes: Miniature Circuit Breakers (MCBs), Moulded Case Circuit Breakers (MCCBs), Air Circuit Breakers (ACBs), fuses, contactors, switch disconnectors, protective relays, busbars, and metering devices, all housed within an enclosure. - What are the key components commonly found in Medium Voltage Switchgear?

MV switchgear typically features: Vacuum Circuit Breakers (VCBs) or SF6 gas circuit breakers, disconnect switches, earthing switches, current transformers (CTs), voltage transformers (VTs), protective relays, busbars, and a metal-enclosed cabinet. - What are the main differences between LV and MV Switchgears?

The main differences lie in their voltage rating, the types of interrupting devices used (e.g., MCCBs/ACBs for LV vs. VCBs/SF6 for MV), their application areas (end-user distribution for LV vs. bulk power distribution for MV), and their physical construction and insulation methods. - What are the common applications of Voltage Switchgear?

LV switchgear is used in residential breaker panels, commercial office buildings, retail spaces, hospitals, data centers, and factories to distribute power to lighting, HVAC systems, small machinery, and general outlets. - What are the common applications of Medium Voltage Switchgear?

MV switchgear is found in power utility substations, large industrial plants (e.g., manufacturing, mining, oil & gas), large commercial complexes, airports, and data centers, where it handles higher power demands and connects to transmission/distribution lines. - What are the common types of Medium Voltage Switchgear by insulation?

MV switchgear can be categorized by its insulation medium:- Air Insulated Switchgear (AIS): Uses atmospheric air for insulation.

- Gas Insulated Switchgear (GIS): Uses an insulating gas (commonly SF6, though “SF6-free” alternatives using pure air or vacuum are emerging) for insulation.

- Solid Insulated Switchgear (SIS): Encapsulates live parts in a solid dielectric material.

- Why is proper compartmentalization important in LV and MV Switchgear?

Extensive compartmentalization (e.g., metallic partitions) increases safety, reliability, and serviceability. It prevents accidental contact with live parts in adjacent sections during maintenance and limits the spread of faults. - What safety features are crucial in both LV and MV Switchgears?

Crucial safety features include: robust enclosures (with IP/IK ratings), mechanical and electrical interlocks to prevent improper operation, arc-flash protection, earth fault protection, and clear labeling. - What international standards do LV and MV Switchgears need to comply with?

Both LV and MV switchgears must comply with international standards like IEC 61439 (for LV assemblies) and IEC 62271 (for MV switchgear and controlgear). Compliance ensures safety, reliability, and interoperability. - What kind of maintenance is required for LV and MV Switchgears?

Regular maintenance is crucial for safety and longevity. It includes: visual inspections (for corrosion, loose connections), cleaning (removing dust, contaminants), tightening connections, insulation testing, thermal imaging (identifying hot spots), and functional testing of circuit breakers and relays. - How often should Switchgears be maintained?

Frequency depends on factors like application (mission-critical vs. general use), environmental conditions (dust, humidity ), age, and load patterns. Generally, annual diagnostic maintenance and quarterly visual inspections are recommended for critical systems. - What are the benefits of modular LV and MV Switchgear designs?

Modular designs offer flexibility, ease of expansion, faster installation, and simplified maintenance, as individual bays or sections can be isolated or replaced without affecting the entire system. - Does ZAJCO SA.com manufacture or supply Medium & Low Voltage Switchgears?

Yes, ZAJCO SA.com’s product page indicates they undertake the manufacture of a comprehensive range of low and medium voltage switchgear, including various types of distribution boards (MDBs, SMDBs, Final DBs), Motor Control Centers (MCCs), Power Factor Control Boards, and specific kiosks, adhering to specifications and international standards like SABS IEC 60439. - What services does ZAJCO SA.com provide related to Switchgears?

As a specialized provider, ZAJCO SA.com offers end-to-end services, including design and engineering (tailored to specific customer needs), manufacturing, supply, testing (Type Tested Assemblies), installation, commissioning, and likely ongoing maintenance and repair services for their switchgear solutions. - Why choose a specialized manufacturer/supplier like ZAJCO SA.com for Switchgears?

Choosing a specialist ensures: high-quality products designed for the demanding UAE climate, compliance with stringent local utility and safety regulations, customized solutions for diverse applications, local manufacturing capabilities for quicker delivery and tailored designs, and reliable local support and after-sales service, which is critical for essential power distribution infrastructure.